T E A

M P E N S K E

R e y n a r

d 9 7 I / M e r c

e d e s T e s t - C

a r

C

O N S T R U C T I

O N

T E A

M P E N S K E

R e y n a r

d 9 7 I / M e r c

e d e s T e s t - C

a r

C

O N S T R U C T I

O N

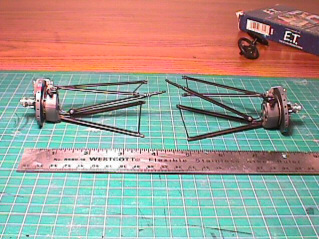

Among the most visible differences between the '97 and '98 Reynard

chassis reside in the aero-package. Above, modified components are test-fitted

for accuracy: the ruler pictured gives an idea of the size of the car in

1/8 scale.

The majority of the bodywork on the car is 6K fiberglass, with

only the monocoque being molded in polyeurethane: each piece must be meticulously

hand-laminated and precisely-cut to accomodate adjoining pieces. This is

a particularly long and pains-taking process which does not allow for mistakes.

Below left: frontal view of a partially-finished right-front suspension

and upright assembly.

Below right: suspension assemblies viewed from both angles. This

particular set of geometries will be fitted to a super-speedway car, as

denoted by the carbon-composite rotors.

Among the most visible differences between the '97 and '98 Reynard

chassis reside in the aero-package. Above, modified components are test-fitted

for accuracy: the ruler pictured gives an idea of the size of the car in

1/8 scale.

The majority of the bodywork on the car is 6K fiberglass, with

only the monocoque being molded in polyeurethane: each piece must be meticulously

hand-laminated and precisely-cut to accomodate adjoining pieces. This is

a particularly long and pains-taking process which does not allow for mistakes.

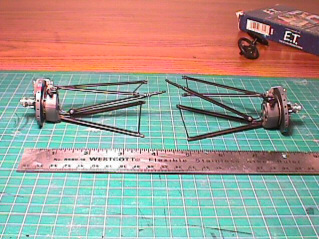

Below left: frontal view of a partially-finished right-front suspension

and upright assembly.

Below right: suspension assemblies viewed from both angles. This

particular set of geometries will be fitted to a super-speedway car, as

denoted by the carbon-composite rotors.

Below left: brake calipers, pads and fixtures are clearly visible

in this view. The wheel nuts are turned metal.

Below right: both wishbone assemblies viewed frontally. Once fitted

to the monocoque, these will give the model its proper maximum width of

25 centimeters.

Below left: brake calipers, pads and fixtures are clearly visible

in this view. The wheel nuts are turned metal.

Below right: both wishbone assemblies viewed frontally. Once fitted

to the monocoque, these will give the model its proper maximum width of

25 centimeters.